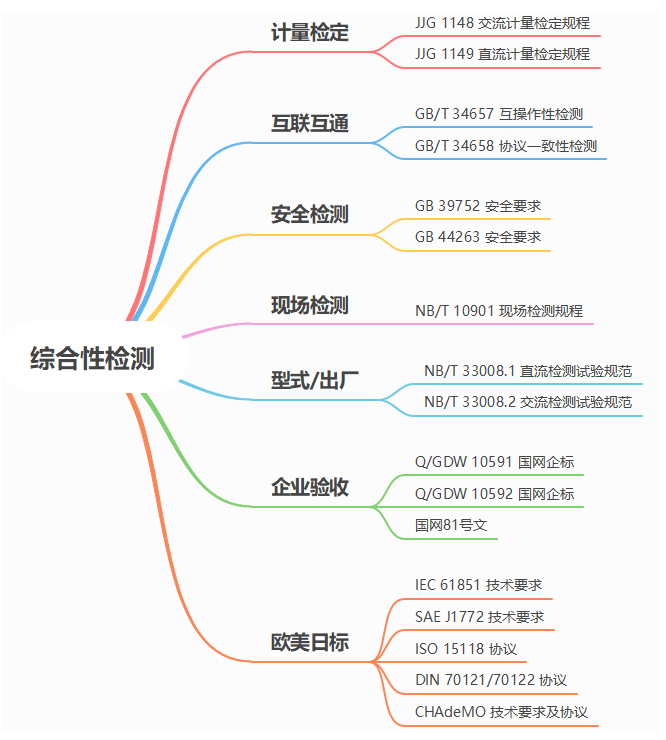

With the continuous growth in the number of charging piles, government agencies have increasingly focused on aspects such as safety, metering, interoperability, and performance of charging piles, formulating and issuing various types of standards to ensure the safety and interoperability of charging piles. Therefore, there are also many types of testing solutions for charging piles.

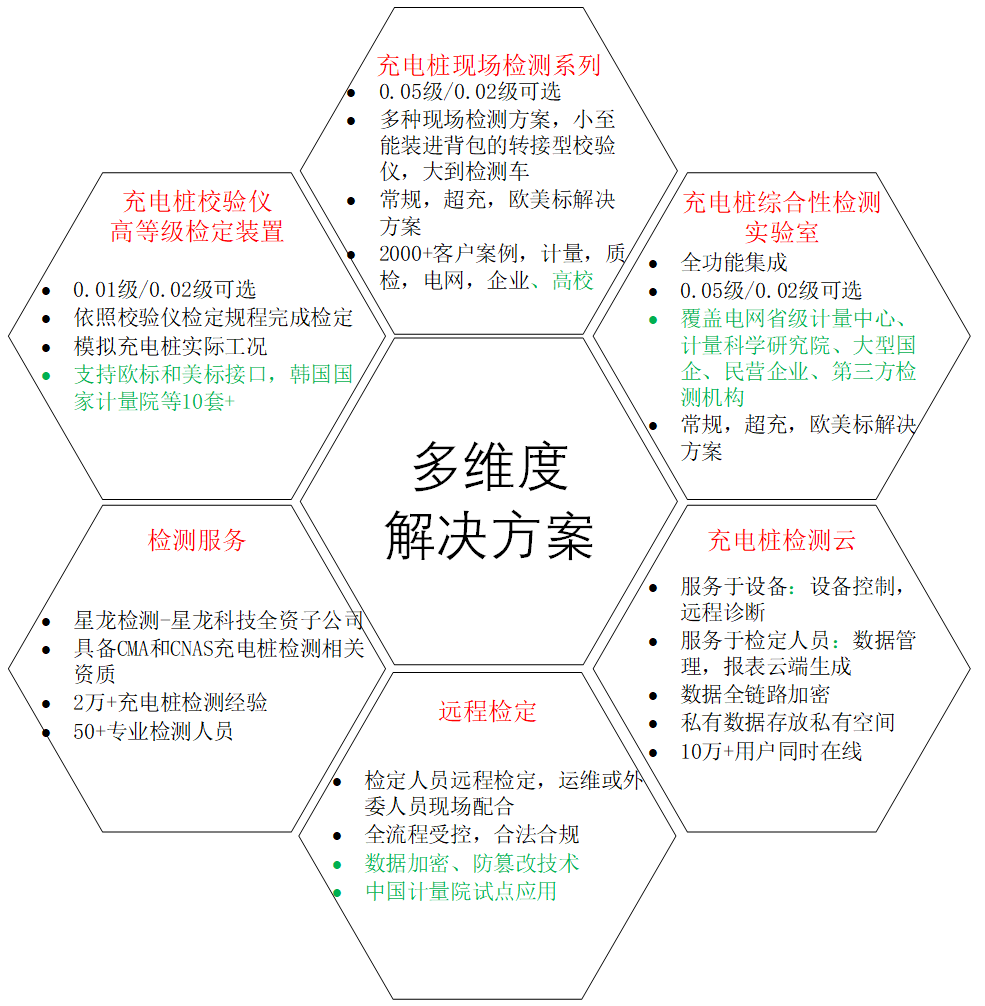

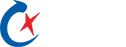

From the classification of testing items, charging pile testing is mainly divided into metrological verification, interoperability testing, protocol consistency testing, and comprehensive testing; from the classification of testing scenarios, charging pile testing is mainly divided into laboratory testing before installation, on-site testing after installation, and periodic metrological verification; from the classification of charging pile testing equipment forms, it is divided into comprehensive laboratory testing systems, mobile testing vehicles, portable testing devices, adapter-type testing devices, and cloud-based remote testing platforms. Our company provides multi-dimensional solutions for all the above categories as shown in the figure on the right:

1. Metrological Verification

Charging pile metrological verification has been implemented since January 1, 2023, as a mandatory verification and has become a routine task for various metrological testing institutions. Since the launch of charging pile metrological verification, we have closely followed customer feedback and needs on-site:

① Users reported that the load volume is large and cannot be placed in the trunk of a sedan. Our company launched a 30kW high energy density load module in an 8U standard chassis for easy portability;

② Users reported no mains power at the verification site. Our company launched a load powered from the gun nozzle and a tester with a built-in power supply, enabling plug-and-test;

③ Users reported the need to support testing modes using electric vehicles as loads. All our products are equipped with dual AD measurement features, maintaining high accuracy and real-time metering of the dynamic characteristics when electric vehicles are used as loads, achieving high bandwidth and wide range measurement characteristics;

④ Users reported that the existing calibration instrument plus load is inconvenient to carry. Our company launched an adapter-type calibrator that can be carried in a backpack;

⑤ Users reported low efficiency due to metrology personnel traveling on-site. Our company launched a real-time remote verification platform where metrology personnel perform verification in the cloud backend, and on-site maintenance personnel assist with wiring;

⑥……

Through continuous product iteration, our company currently has the following different forms of metrological dedicated calibration equipment

| Type |

Integrated |

Adapter-type |

Characteristic Tester |

Testing Vehicle |

| Model |

XL -942P |

X L-943P |

X L-942Z |

X L-943Z |

XL -942 S (SC) |

XL -943S |

XL -A951 |

| Image |

|

|

|

|

| Index |

Accuracy |

0.05 Grade/ 0.02 Grade |

| Wide Dynamic Range |

100V~1150 V 1A~300A |

Three-phase 220V ± 20% 0.1 A ~80A |

100V~1150 V 1A~300A |

Three-phase 220V ± 20% 0.1 A ~80A |

100V~11500 V 1A~800A |

Three-phase 220V ± 20% 0.1 A ~80A |

100V~1150 V 1A~300A |

Three-phase 220V ± 20% 0.1 A ~80A |

| Characteristics |

Cumulative Energy Refresh Cycle Note |

0.1ms |

0.1ms |

0.1ms |

0.1ms |

0.1ms |

0.1ms |

0.1ms |

0.1ms |

| Measurement Bandwidth Note |

DC ~300kHz |

4 5Hz~30kHz |

DC ~300kHz |

4 5Hz~30kHz |

DC ~300kHz |

4 5Hz~30kHz |

DC ~300kHz |

4 5Hz~30kHz |

| Dual AD Measurement Note |

√ |

|

√ |

|

√ |

|

√ |

|

| Insulation Module |

|

√ |

|

|

√ |

√ |

√ |

√ |

| Testing Tesla Charging Piles |

√ |

√ |

√ |

√ |

√ |

√ |

Expandable |

Expandable |

| Load |

Electric Vehicle |

√ |

√ |

√ |

√ |

√ |

√ |

Expandable |

Expandable |

| Built-in Load |

Built-in 8kW Programmable Load |

- |

With 1 80 kW Load |

| Load Cascading |

√ |

√ |

|

|

√ |

√ |

Expandable |

Expandable |

| Clock |

GPS Clock |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

| NTP Clock Note |

√ |

√ |

√ |

√ |

Expandable |

Expandable |

Expandable |

Expandable |

| Control Method |

Local Screen |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

| W WiFi + Computer |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

| 4G+ Tencent Cloud+ WeChat Mini Program Note |

√ |

√ |

√ |

√ |

Expandable |

Expandable |

Expandable |

Expandable |

| Application Scenarios |

On-site Verification |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

| Remote Verification Note |

√ |

√ |

√ |

√ |

Expandable |

Expandable |

Expandable |

Expandable |

| User Data Platform Integration |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

| Weight |

About 1 5 kg |

About 1 5 kg |

About 4 kg |

About 4 kg |

About 2 5 kg |

About 2 5 kg |

- |

Note 1: Energy Refresh Cycle: Reflects the cumulative energy calculation cycle. The smaller the cycle, the more synchronized it is with the actual cumulative energy, eliminating energy loss caused by waveform sudden changes or continuous variations when using electric vehicles as loads.

Note: Dual AD Measurement: Uses two types of analog-to-digital conversion chips for synchronous sampling at low and high frequencies, leveraging the advantages of high accuracy at low frequency and wide bandwidth at high frequency.

Note 2: Measurement Bandwidth: When using a real vehicle as the load, the waveform contains ripples or rectangular waves with a very wide frequency band and may exhibit transients. The higher the measurement bandwidth, the better these waveform characteristics are preserved, preventing signal distortion that leads to inaccurate energy accumulation.

Note 3: NTP Clock: In places with obstructions such as underground parking lots and campus parking lots, GPS clocks often fail to synchronize. The NTP clock can achieve automatic synchronization as long as the phone has a signal.

Note 4: WeChat Mini Program: Using a WeChat mini program can improve on-site inspection efficiency and meet processes such as photographing charging piles for evidence, cloud data storage, and automatic cloud report generation.

Note 5: Remote Verification: Currently, most charging pile verifications are conducted on-site or by extending verification cycles through remote testing, but remote testing cannot replace verification work. Our company has cooperated with the China Institute of Metrology to develop a remote verification model and has completed multiple batches of remote verification for charging piles. |

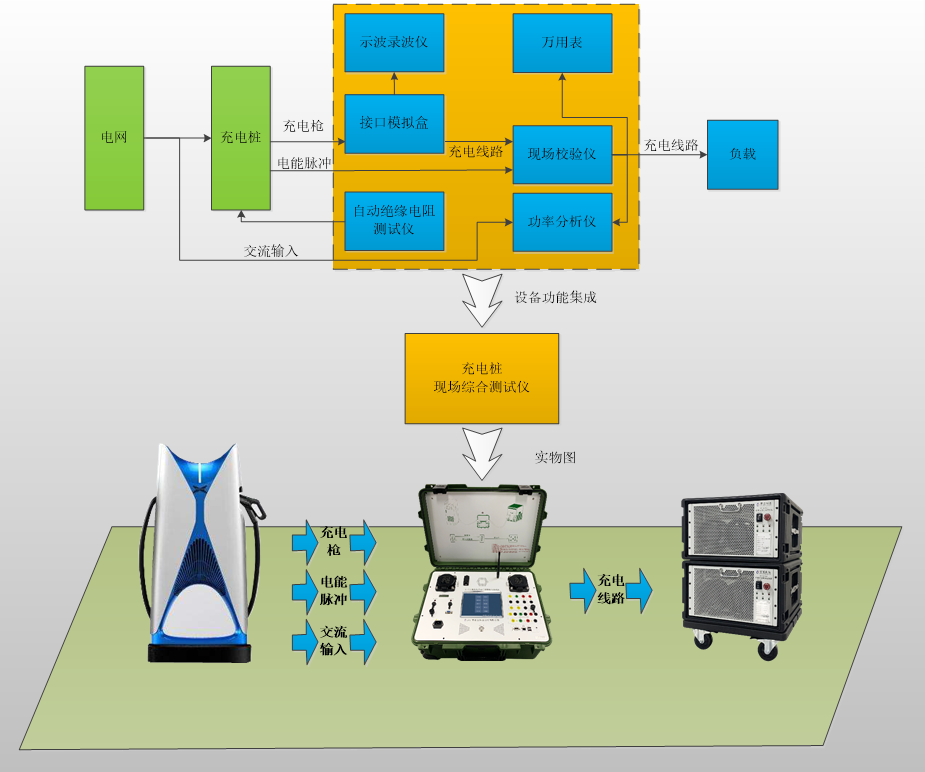

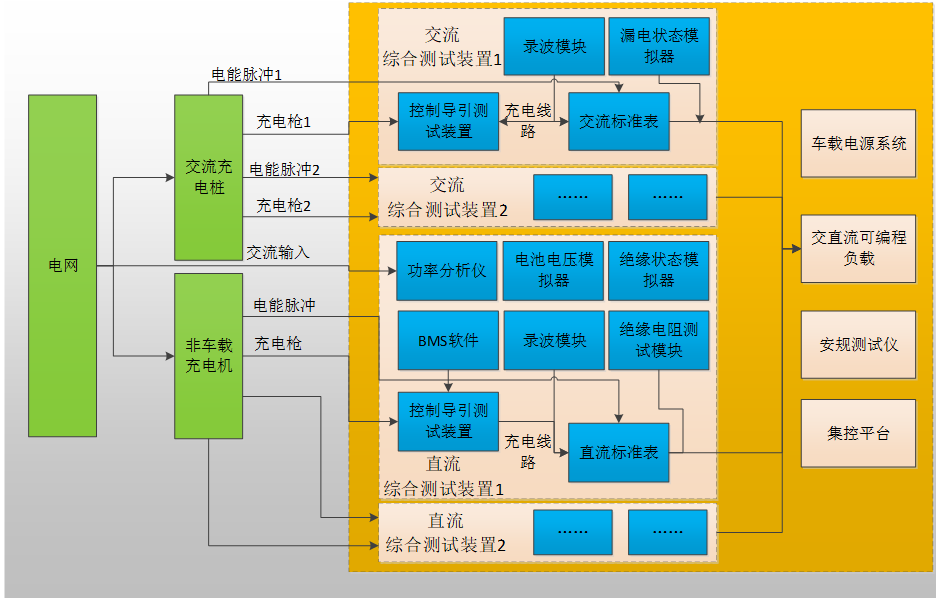

2. Comprehensive Testing Platform

The comprehensive testing platform not only has metrological verification functions but also features interoperability, safety, and comprehensive testing capabilities. According to different testing scenarios, we have designed on-site comprehensive testing devices, vehicle-mounted comprehensive testing platforms, and laboratory comprehensive testing platforms to meet various user needs.

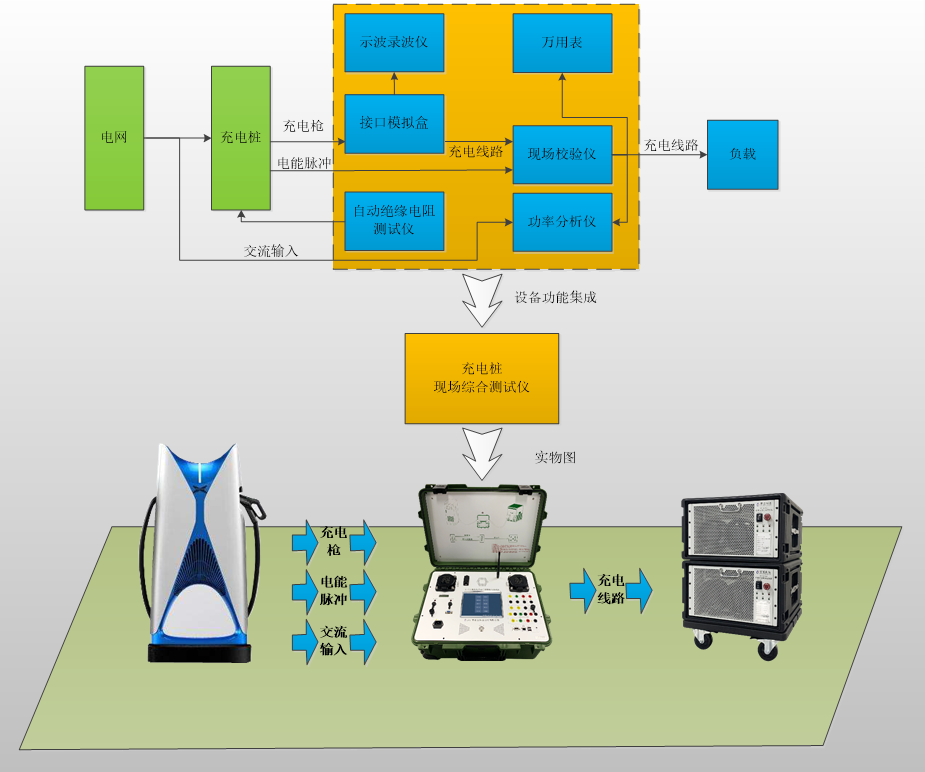

1) On-site Comprehensive Testing Device

To solve the difficulties and inefficiencies of carrying various equipment needed for on-site charging pile testing, our company launched a highly integrated series of on-site charging pile calibration instruments. This greatly reduces the number of devices carried on-site, integrating modules such as insulation resistance testers, power analyzers, and waveform recorders. The number of devices carried on-site is reduced from 7 to 2, greatly improving portability, significantly reducing on-site wiring, and enhancing automation and coordination, thereby greatly improving on-site testing efficiency.

Functional Features:

① Meets on-site testing requirements for 2015+ and Chaoji charging piles, supporting testing of supercharging piles up to 1500V, 800A;

② Full waveform recording, with messages and analog signals displayed on the same coordinate system, featuring cursor functions for signal timing measurement;

③ Fully complies with JJG 1148/1149-2022 metrological verification, GB/T34657.1-2017 interoperability, GB/T 34658-2017 protocol consistency, NB/T10901 on-site testing procedures, and State Grid Document No. 81 testing requirements. One device tests all content;

④ Uses multi-closed-loop zero-flux sensors based on "fluxgate technology" combined with electronic PGA technology. DC measurement achieves accuracy better than 0.05% over a wide range, with full-scale accuracy better than 0.01%;

⑤ Employs 512x oversampling and 24-bit AD technology. AC measurement achieves accuracy better than 0.05% over a wide range, with full-scale accuracy better than 0.01%;

⑥ Highly integrated solution reduces the number of devices needed for comprehensive testing from 8 to 3, greatly improving portability, significantly reducing on-site wiring complexity, and enhancing on-site testing efficiency and safety.

| Model |

Product Name |

Product Image |

Main Functions |

Grade |

Relevant Standards |

Selection Notes |

| XL-943S |

AC Charging Pile On-site Characteristic Tester |

|

For metrological verification, interoperability testing, and on-site testing of AC charging piles |

Class 0.05 |

JJG 1148-2022 "Verification Regulations for Electric Vehicle AC Charging Piles" GB/T 34657.1-2017 "Electric Vehicle Conductive Charging Interoperability Test Specification Part 1: Power Supply Equipment" NB/T 10901-2021 "Technical Specifications for On-site Inspection of Electric Vehicle Charging Equipment" |

Comprehensive functions, high cost performance |

| XL-942S |

Non-vehicle-mounted Charger On-site Characteristic Tester |

|

For metrological verification, interoperability testing, protocol consistency testing, and on-site testing of DC charging piles |

Class 0.05 |

JJG 1149-2022 "Verification Regulations for Electric Vehicle Non-vehicle-mounted Chargers" GB/T 34657.1-2017 "Electric Vehicle Conductive Charging Interoperability Test Specification Part 1: Power Supply Equipment" GB/T 34658-2017 "Protocol Consistency Testing Between Electric Vehicle Non-vehicle-mounted Conductive Chargers and Battery Management Systems" NB/T 10901-2021 "Technical Specifications for On-site Inspection of Electric Vehicle Charging Equipment" |

Comprehensive functions, high cost performance |

| XL-942SC |

Supercharger On-site Characteristic Tester |

|

For 2 015+ and Chaoji interface supercharger metrological verification, interoperability testing, protocol consistency testing, and on-site testing |

Class 0.05 |

JJG 1149-2022 "Verification Regulations for Electric Vehicle Non-vehicle-mounted Chargers" GB/T 34657.1-2017 "Electric Vehicle Conductive Charging Interoperability Test Specification Part 1: Power Supply Equipment" GB/T 34658-2017 "Protocol Consistency Testing Between Electric Vehicle Non-vehicle-mounted Conductive Chargers and Battery Management Systems" NB/T 10901-2021 "Technical Specifications for On-site Inspection of Electric Vehicle Charging Equipment" |

Comprehensive functions, high cost performance |

2) Vehicle-mounted Comprehensive Testing Platform

To solve the current difficulties in carrying equipment for on-site testing and overcome the poor applicability of charging pile testing vehicles on the market, our company launched a highly applicable, fully functional, and highly efficient mobile testing platform. This platform has the following features:

① Optional electric vehicle platform or fuel vehicle platform;

② Single or dual gun freely selectable; supports up to two AC guns or two DC guns tested simultaneously;

③ Vehicle height less than 2 meters, freely entering various venues including low-clearance parking lots; drivable with a Class C driver's license; highly applicable;

④ Full-function testing capability, meeting JJG 1148/1149-2022 metrological verification, GB/T 34657.1 interoperability testing, GB/T 34658 protocol consistency testing, and the forthcoming NB/T 10901-2021 technical specifications for on-site inspection of electric vehicle charging equipment;

⑤ Uses multi-closed-loop zero-flux sensors based on "fluxgate technology" combined with electronic PGA technology. DC measurement achieves accuracy better than 0.05% over a wide range, with full-scale accuracy better than 0.01%, fully meeting JJG1148 and 1149 verification test requirements;

⑥ Multi-channel process waveform recording, with recorded data supporting offline loading and cursor measurement, making the testing process traceable;

| Model |

Product Name |

Product Image |

Main Functions |

Grade |

Relevant Standards |

Selection Notes |

| XL-951 |

AC/DC Charging Pile Mobile Testing Platform (Testing Vehicle) |

|

For metrological verification, interoperability testing, protocol consistency testing, on-site energy standards, and laboratory energy standards (partial) of AC and DC charging piles. |

Class 0.05 |

JJG 1148-2022 "Verification Regulations for Electric Vehicle AC Charging Piles" JJG 1149-2022 "Verification Regulations for Electric Vehicle Non-vehicle-mounted Chargers" GB/T 34657.1-2017 "Electric Vehicle Conductive Charging Interoperability Test Specification Part 1: Power Supply Equipment" GB/T 34658-2017 "Protocol Consistency Testing Between Electric Vehicle Non-vehicle-mounted Conductive Chargers and Battery Management Systems" NB/T 10901-2021 "Technical Specifications for On-site Inspection of Electric Vehicle Charging Equipment" NB/T 33008.1-2018 "Electric Vehicle Charging Equipment Inspection and Testing Specification Part 1: Off-board Chargers" NB/T 33008.2-2018 "Electric Vehicle Charging Equipment Inspection and Testing Specification Part 2: AC Charging Piles" |

Comprehensive functionality , excellent operational experience, mobile laboratory |

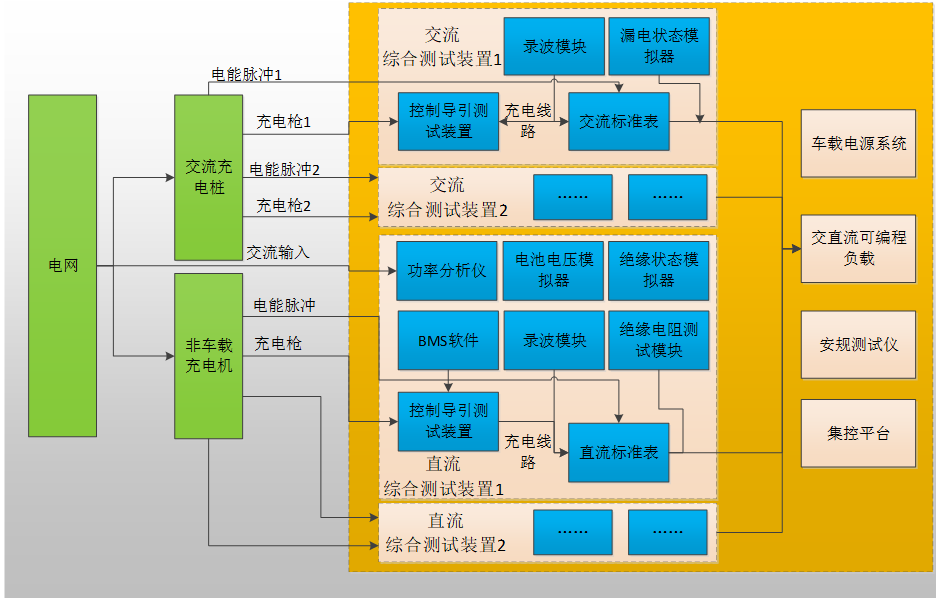

3) Comprehensive laboratory testing platform

With increasing requirements for the safety and interoperability of charging piles, the government mandates 3C compulsory testing for charging piles and also requires type testing. This platform supports both 3C testing and type testing of charging piles, and can be extended to test European, American, and Japanese standard charging piles within 1500V and 1000A. The platform can freely combine power supplies and regenerative resistive loads, record waveforms throughout the process, and display test details through waveform charts for intuitive understanding of the project’s testing status. In addition to the above features, the platform also offers the following:

① Numerous cases: Provincial or higher-level institutions such as the China Institute of Metrology and China Automotive Technology & Research Center have used this platform for daily work;

② This solution has been applied as 3C testing equipment in the first batch of 25 charging pile 3C testing agencies designated by the Certification and Accreditation Administration of China;

③ Expandable to European, American, and Japanese standards, with European and American standards featuring true protocol consistency testing, comparable to internationally renowned brand Vector’s testing equipment;

④ "Non-intrusive" testing technology, completing the entire testing wiring without internal wiring of the charging pile, ensuring safety and efficiency;

⑤ "Modular" design concept, power supplies and loads can be expanded in parallel, allowing the platform capacity to be achieved in one step or gradually upgraded according to actual conditions, with no worries for the future;

⑥ Using multi-closed-loop zero-flux sensors based on fluxgate technology combined with electronic PGA technology, DC measurement can achieve accuracy better than 0.05% over a wide range, with full-scale accuracy better than 0.01%, fully meeting JJG1148 and JJG1149 metrological verification tests;

⑦ Multi-channel process waveform recording, automatic active waveform capture, with traceable testing process;

Capable of completing the following standard tests:

| Serial Number |

Standard Name |

| 1 |

GB 39752-2024 Safety Requirements for Electric Vehicle Power Supply Equipment |

| 2 |

GB 44263-2024 Safety Requirements for Electric Vehicle Conductive Charging Systems |

| 3 |

NB/T 33008.1-2018 Electric Vehicle Charging Equipment Inspection and Testing Procedures Part 1: Off-board Chargers |

| 4 |

NB/T 33008.2-2018 Electric Vehicle Charging Equipment Inspection and Testing Procedures Part 2: AC Charging Piles |

| 5 |

JJG1148-2022 Verification Procedures for Electric Vehicle AC Charging Piles |

| 6 |

JJG1149-2022 Verification Procedures for Electric Vehicle Off-board Chargers |

| 7 |

GB/T 34657.1-2017 Electric Vehicle Conductive Charging Interoperability Testing Specification Part 1: Power Supply Equipment |

| 8 |

GB/T 34658-2017 Protocol Consistency Testing between Electric Vehicle Off-board Conductive Chargers and Battery Management Systems |

| 9 |

NB/T 10901-2021 Technical Specification for On-site Inspection of Electric Vehicle Charging Equipment |

| 10 |

Marketing Intelligence [2018] No. 45 Notice from the State Grid Marketing Department on Issuing the Work Plan to Further Strengthen Quality Evaluation of Electric Vehicle Charging Equipment |

| Model |

Product Name |

Product Image |

Main Functions |

Grade |

Relevant Standards |

Selection Notes |

| XL-A911 |

AC and DC Charging Pile Laboratory Testing Platform |

|

For AC and DC charging piles, 3C certification testing , R&D assistance, metrological testing, interoperability testing, protocol consistency, comprehensive energy standards testing, State Grid No. 45 document testing projects, type testing, Expandable to European, American, and Japanese standards, expandable to group charging testing |

Class 0.05 |

GB 39752-2024 Safety Requirements for Electric Vehicle Power Supply Equipment GB 44263-2024 Safety Requirements for Electric Vehicle Conductive Charging Systems JJG 1148-2022 "Verification Regulations for Electric Vehicle AC Charging Piles" JJG 1149-2022 "Verification Regulations for Electric Vehicle Non-vehicle-mounted Chargers" GB/T 34657.1-2017 "Electric Vehicle Conductive Charging Interoperability Test Specification Part 1: Power Supply Equipment" GB/T 34658-2017 "Protocol Consistency Testing Between Electric Vehicle Non-vehicle-mounted Conductive Chargers and Battery Management Systems" NB/T 33008.1-2018 "Electric Vehicle Charging Equipment Inspection and Testing Specification Part 1: Off-board Chargers" NB/T 33008.2-2018 "Electric Vehicle Charging Equipment Inspection and Testing Specification Part 2: AC Charging Piles" Marketing Intelligence [ 2018] No. 45 Notice from the State Grid Marketing Department on Issuing the Work Plan to Further Strengthen Quality Evaluation of Electric Vehicle Charging Equipment |

High-performance, comprehensive advanced testing platform |