Solution Details

DC Power Traceability Testing Solution

1. Introduction

With the rapid development of the new energy industry and the deepening transformation of the global energy structure, the application fields of DC energy measurement devices continue to expand and show diversified development trends. DC energy measurement devices mainly include DC energy meters, DC shunts, DC standard energy meters, DC energy meter calibration devices, and DC shunt calibration devices; DC energy meters are mainly used in new energy sources such as charging piles, photovoltaics, and wind power, and are divided into direct DC energy meters and indirect DC energy meters; DC shunts are mainly used for large current I/V conversion and are often used in conjunction with indirect energy meters; DC standard energy meters serve as DC energy standards to test other devices, with the highest accuracy class of 0.01; DC energy meter calibration devices include single-position and multi-position calibration devices used for testing DC energy meters; DC shunt calibration devices include single-position and multi-position calibration devices used for testing DC shunts.

2. Relevant Regulations and Standards

(1) National Metrology Calibration Procedures and Standards

1. JJG-842-2017 "Calibration Procedure for Electronic DC Meters": This procedure applies to the initial and subsequent calibration of electronic DC energy meters.

2. JJF 1779-2019 "Type Evaluation Outline for Electronic DC Energy Meters": This procedure applies to the type evaluation of electronic (static) DC energy meters classified under metrological instrument code 15262500 with accuracy classes 0.2, 0.5, 1, and 2.

3. JJG-842-2017 "Calibration Procedure for Electronic DC Meters": This procedure applies to the initial and subsequent calibration of electronic DC energy meters.

4. GB/T 33708-2017 "Static DC Energy Meters": This standard specifies the terminology, requirements, test methods, and inspection rules for static DC energy meters.

5. JJG1069-2011 "Calibration Procedure for DC Shunts": This procedure applies to the initial calibration, subsequent calibration, and in-use inspection of DC shunts with rated input currents from 5A to 10kA and accuracy classes from 0.02 to 2, composed of copper terminals and plate or rod-shaped resistive elements. It also applies to the calibration of high-power standard resistors used for measuring large DC currents.

6. JJG 1186-2022 "Calibration Procedure for DC Energy Meter Calibration Devices": This procedure applies to the initial calibration, subsequent calibration, and in-use inspection of DC energy meter calibration devices.

7. JJG 1187-2022 "Calibration Procedure for DC Standard Energy Meters": This procedure applies to the initial calibration, subsequent calibration, and in-use inspection of DC standard energy meters.

(2) Enterprise Standards

1. QGDW-1825-2013 "Technical Specifications for DC Energy Meters"

2. QCSG 1209018-2019 "Technical Specifications for DC Energy Meter Inspection Devices"

(3) Standards to be Improved

1. Revised version of GB/T 33708 "DC Energy Measurement Devices", Part 1: General Requirements: Specifies the general requirements for DC energy measurement devices and related tests and type test conditions, detailing functional requirements, mechanical requirements, electrical requirements, safety requirements, marking requirements, and test methods and conditions for electromagnetic and climatic environmental immunity.

2. Revised version of GB/T 33708 "DC Energy Measurement Devices", Part 2: General Requirements: Specifies the terminology and definitions for indirectly connected static DC energy meters, standard electrical quantities, structural requirements, instrument markings and documentation, metrological performance, climatic environmental requirements, external influences, type tests, and safety performance requirements.

(4) Other Standards

1. DL/T 2345—2021 "Technical Specifications for External Shunts of DC Energy Meters": Details the technical requirements, test methods, and verification acceptance for external shunts of DC energy meters.

3. Application Scenarios

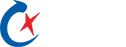

(1) DC Energy Meter Testing

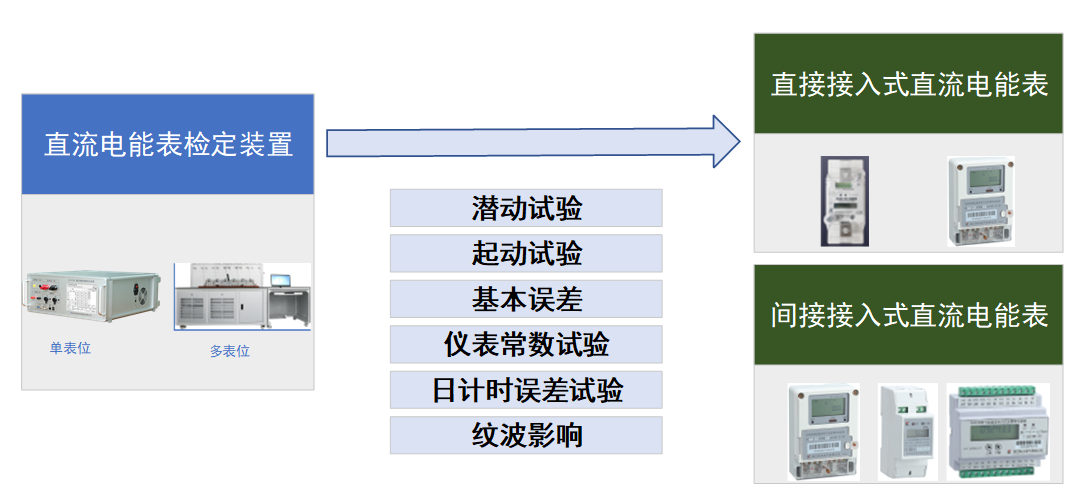

(2) DC Shunt Testing

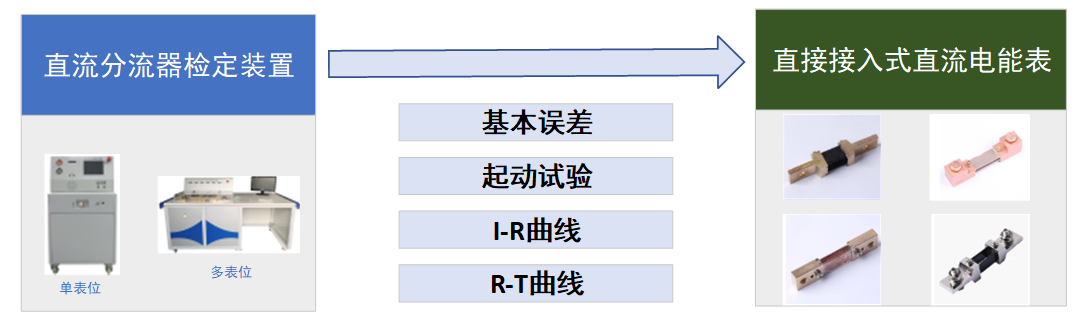

(3) DC Energy Traceability Testing

Next

Previous Page

Next Page

Related Products

XL-9100 DC Electric Energy Meter Calibration Device

XL-9600T6 DC Meter Calibration Device