XL-A3436 Three-Phase AC Programmable Load

The XL-A3433 three-phase AC programmable load is our company's sincere contribution to electric vehicle charging pile enterprises and related institutions. This product is mainly used as a load for the laboratory verification of electric vehicle charging piles. When used with our company's AC charging pile comprehensive test device XL-A603, it can realize the laboratory testing process of AC charging piles. The entire testing process complies with the requirements of national relevant testing standards and metrology standards "JJG 1148-2022 Verification Regulations for Electric Vehicle AC Charging Piles."

Product Description

Product Introduction

The XL-A3433 three-phase AC programmable load is our company's sincere contribution to electric vehicle charging pile enterprises and related institutions. This product is mainly used as a load for laboratory verification of electric vehicle charging piles. When used with our AC charging pile comprehensive test device XL-A603, it can realize the laboratory testing process of AC charging piles. The entire testing process complies with the national relevant testing standards and metrology standards "JJG 1148-2022 Electric Vehicle AC Charging Pile Verification Regulations."

The internal mainboard of the resistive load box uses a processor chip based on the ARM Cortex-M4 core architecture, automating the entire workflow of the resistive load box, reducing manual involvement, and saving operation time. Internally, it adopts a multi-channel high-power resistor parallel structure, controlled by high-quality relays. Various gear switching can be achieved by controlling the relays, making the entire process fully automated without manual intervention. Forced air cooling is used, with a simple circuit structure requiring minimal maintenance, saving cooling costs. Temperature detection is set inside to monitor the working temperature in real-time, ensuring safety and reliability during load use. The box is equipped with standard-compliant AC sockets for easy user cascading and increased load power.

Application Scope

As a laboratory test load for charging piles, aging load, cabinet type, and flexibly movable. The XL-A3433 can be used with the AC charging pile laboratory test system as a load for AC charging piles, meeting the requirements for charging pile operating points in metrology testing, completing the full set of tests for type tests and factory inspections of AC charging piles.

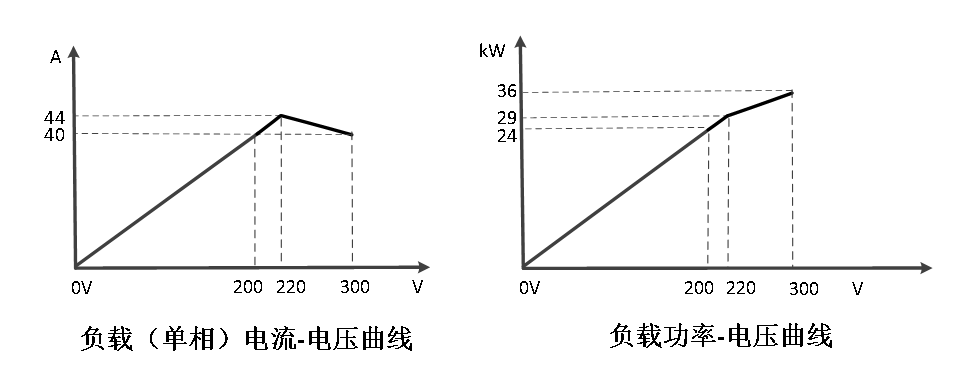

Single Load Operating Curve

Features

1. Achieves the power verification points required by "JJG 1148-2022 Electric Vehicle AC Charging Pile Verification Regulations";

2. At rated voltage, minimum current step of 10mA, minimum power step of 2W, with a total of 8192 levels, achieving stepless switching;

3. The load box features advanced control algorithms and DSP digital control, suitable for various high-precision, high-speed, and high-stability load regulation requirements;

4. Can be remotely controlled via local touch display or serial port; the human-machine interface is designed for ease of operation;

5. Equipped with emergency stop protection, overcurrent, overvoltage, and short circuit protection functions;

6. Features dynamic cooling mode, adjusting cooling intensity in real-time based on load temperature, balancing energy-saving quiet operation and strong cooling;

7. The box uses national standard charging gun sockets, meeting IPXXC protection level to prevent electric shock accidents from finger contact with live parts. Loads can be expanded by cascading; two units cascaded can achieve 48kW power capacity;

8. The device can be powered by mains or charging pile power supply modes, solving the anxiety of no mains power available at the test site;

9. Real-time temperature monitoring triggers automatic protection measures and alarms when overheating occurs. Additionally, load temperature information can be obtained remotely in real-time via communication interface;

10. Capable of simulating the entire charging process of various electric vehicle power batteries, such as constant current mode, constant power mode, constant resistance mode, etc. The device includes voltage and current calibration correction functions, allowing calibration and correction of instrument measurements at any time to ensure long-term measurement accuracy.

Testing Items (can complete the following standard test items)

- "JJG 1149-2022 Electric Vehicle Off-board Charger Verification Regulations"

- "GB/T 34657.1-2017" Conductive Charging Interoperability Test Items

- "GB/T 34658-2017" Communication Protocol Consistency Test Items

- "NB/T 33008.1-2018" Type Test Items

- "GB 39752-2024 Electric Vehicle Power Supply Equipment Safety Requirements"

- "GB 44263-2024 Electric Vehicle Conductive Charging System Safety Requirements"

Technical Specifications

| 1. Load Voltage | |

| Input Voltage | 0~264VAC (phase voltage) 0~380VAC (line voltage) |

| 2. Load Current | |

| Single Unit Current Input | 0A~40A (@380V) (three-phase) |

| Cascaded Current Input | 0A~80A (@380V) (three-phase) |

| 3. Load Power | |

| Single Unit Power Input | 0kW~24kW (three-phase) |

| Cascaded Power Input | 0kW~48kW (three-phase) |

| 4. Load Levels | |

| Number of Levels | 8192 |

| Minimum Current Step | 0.01A (@220V) |

| Minimum Power Step | 0.022kW (@220V) |

| 5. Constant Current Mode | |

| Range | 1A~40A |

| Resolution | 0.1A (@220V) |

| Accuracy | ±(0.1%+0.5%FS) |

| 6. Constant Power Mode | |

| Range | 24kW |

| Resolution | 1VA (@220V) |

| Accuracy | ±(0.2%+0.5%FS) |

| 7. Constant Resistance Mode | |

| Range | 5Ω~5000Ω |

| Resolution | 1Ω |

| Accuracy | 0.1%+0.0008S |

| 8. Cascade | |

| Whether cascade is supported | Yes |

| 9. Device Operating Power Supply | |

| Rated Input | AC220V |

| Input Range | 100%±10% |

| 10. Other Indicators | |

| Power Supply | AC85~265V, 50Hz/60Hz |

| Relative Humidity | ≤85%, no corrosive gases |

| Overall Dimensions | 600mm*700mm*1800mm (W*D*H) |

Product Document

File Name

Update Time

Related Products

XL-A922C Super Charging Pile Comprehensive Testing System

XL-A923F AC Charging Pile Factory Testing Platform

XL-A922F Non-Vehicle Onboard Charger Factory Testing Platform

XL-A923S Series Comprehensive Test System for AC Charging Piles in China, Europe, and America

XL-A392D DC Short Circuit Test Device

XL-A392A AC Short Circuit Test Device

XL-A672 DC Charging Pile Connector Overtemperature Simulator

XL-A501C Supercharge Charging Simulator

Product Inquiry