XL-A3612 DC Programmable Load

The XL-A3612 DC programmable load is our company's sincere contribution to electric vehicle charger enterprises and related institutions. This product is mainly used as a programmable, electronically switched resistive load for our company's off-board charger laboratory testing platform and off-board charger field testing instruments. It features on-demand stepping and multi-unit cascading operation. It meets the load requirements of relevant standards and regulations such as "JJG 1149-2022 Electric Vehicle DC Charger Verification Regulations" and "NB/T 33008.1~33008.2-2018 Electric Vehicle Charging Equipment Testing Specifications."

Product Description

The XL-A3612 DC programmable load is our company's sincere contribution to electric vehicle charger enterprises and related institutions. This product is mainly used as a programmable, automatic gear-shifting electronic resistive load for our company's off-board charger laboratory test platform and off-board charger field test instruments. It features stepwise operation on demand and multi-box cascading; it meets the load requirements of standards and regulations such as "JJG 1149-2022 Electric Vehicle DC Charger Verification Regulations" and "NB/T 33008.1~33008.2-2018 Electric Vehicle Charging Equipment Testing Specifications."

Design Specifications

- Safety Specifications: DC1500V safety design;

- Ambient Temperature: -20℃ to 45℃;

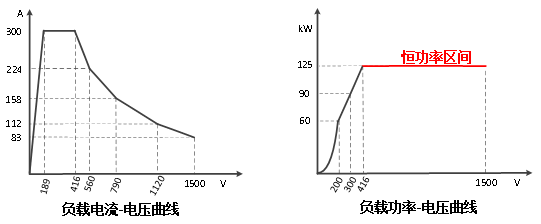

- Operating Curve:

Functional Features

1. Capable of achieving power and energy verification points required by "JJG 1149-2022 Electric Vehicle Off-board Charger Verification Regulations" and "NB/T 33008.1~33008.2-2018 Electric Vehicle Charging Equipment Testing Specifications";

2. Equipped with automatic gear-shifting function; at rated voltage, minimum current step is 0.009A, with 262,144 levels per device;

3. Features constant power function, covering the full voltage range of 416V to 1500V in the constant power zone;

4. Capable of simulating the entire charging process of electric vehicle power batteries, such as constant current mode, constant voltage mode, constant power mode, constant resistance mode, etc.;

5. Has voltage and current calibration correction functions, allowing calibration and correction of the load's resistance levels at any time to ensure loading accuracy during long-term use;

6. Supports cascading expansion, with DC maximum expansion up to 1250kW;

7. Equipped with multiple communication interfaces such as RS-232 and CAN;

8. Can be controlled via local touch display or serial port, with a user-friendly human-machine interface for easy operation;

9. The load features powerful control algorithms and DSP digital control, suitable for various high-precision, high-speed, and high-stability load regulation requirements;

10. Features dynamic cooling mode, adjusting cooling intensity in real time based on load temperature, achieving both energy-saving quiet operation and strong cooling;

11. Uses forced air cooling, with an ARM Cortex-M4 based mainboard controlling relays to manage cooling system fans, efficiently cooling the device while saving power costs;

12. Equipped with intelligent fan temperature control; when the load box temperature is too high, it actively disconnects the load for high-temperature protection and issues an alarm; when the temperature reaches a safe level, the fan stops automatically; temperature inside the box can also be monitored via debugging serial port;

13. Features emergency stop function, allowing immediate disconnection of the charging circuit and load levels in case of emergencies; the fan continues to operate to prevent internal component damage from overheating, ensuring personnel safety and property protection;

Each load has a built-in 400A fuse for short-circuit protection and also includes overcurrent, overvoltage, and overtemperature protection functions.

Technical Specifications

| 1. Load Voltage | |

| DC Input Voltage | 0 to 1500V DC |

| 2. Load Current | |

| Maximum DC Input Current | 0 to 300A DC |

| 3. Load Power | |

| Maximum DC Power | 0 to 125kW |

| 4. Load Levels | |

| Number of Levels | 262144 |

| Number of Cascadable Units | 10 |

| Minimum Current Step | 0.009A (@1500V) |

| Minimum Power Step | 13.7W (@1500V) |

| 5. Constant Voltage Mode | |

| Range | 100 to 1500V |

| Resolution | 0.1V |

| Accuracy | ±(0.1% + 0.5% F.S.) |

| 6. Constant Current Mode | |

| Range | 0 to 300A |

| Resolution | 0.1A |

| Accuracy | ±(0.1% + 0.5% F.S.) |

| 7. Constant Power Mode | |

| DC Measurement Range | 0 to 125kW |

| Resolution | 1VA |

| Measurement Accuracy | ±(0.2% + 0.5% F.S.) |

| 8. Constant Resistance Mode | |

| AC/DC Measurement Range | 0.63Ω to 5000Ω |

| Resolution | 1Ω |

| Measurement Accuracy | 0.1% + 0.0008S) |

| 9. Other Specifications | |

| Power Supply | 85 to 220V AC ±10%, 50Hz/60Hz |

| Operating Ambient Temperature | -20 to 50°C |

| Relative Humidity | ≤85%, non-corrosive gases |

| Dimensions (excluding wheels) | 590mm * 600mm * 1700mm (W * D * H); |

| Weight | Approximately 120kg |

Product Document

File Name

Update Time

Related Products

XL-A922C Super Charging Pile Comprehensive Testing System

XL-A923F AC Charging Pile Factory Testing Platform

XL-A922F Non-Vehicle Onboard Charger Factory Testing Platform

XL-A923S Series Comprehensive Test System for AC Charging Piles in China, Europe, and America

XL-A392D DC Short Circuit Test Device

XL-A392A AC Short Circuit Test Device

XL-A672 DC Charging Pile Connector Overtemperature Simulator

XL-A501C Supercharge Charging Simulator

XL-A3436 Three-Phase AC Programmable Load

Product Inquiry